Custom Injection Molding Mould Food Grade Plastic Bottle Water Cap

Overview Custom Injection Molding Mould Food Grade Plastic Bottle Water Cap Advantages: 1. Free design and free sample.

Overview

1. Free design and free sample.

2. Sign NDA.

3. ISO Certificated with the strict quality control system.

4. 13 Years OEM&ODM Mould-making,metal and plastic processing experience.

5. Good at spoken english and phone call communication.

6.One stop solution and drop shipment for online sellers.

Product Description

Products show

Services

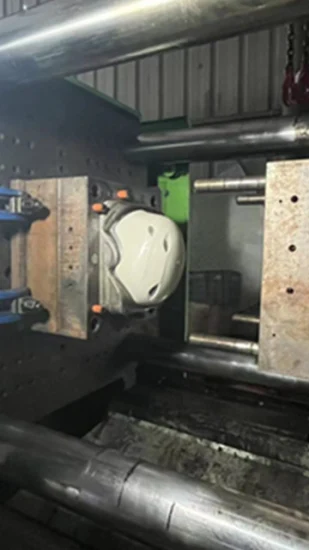

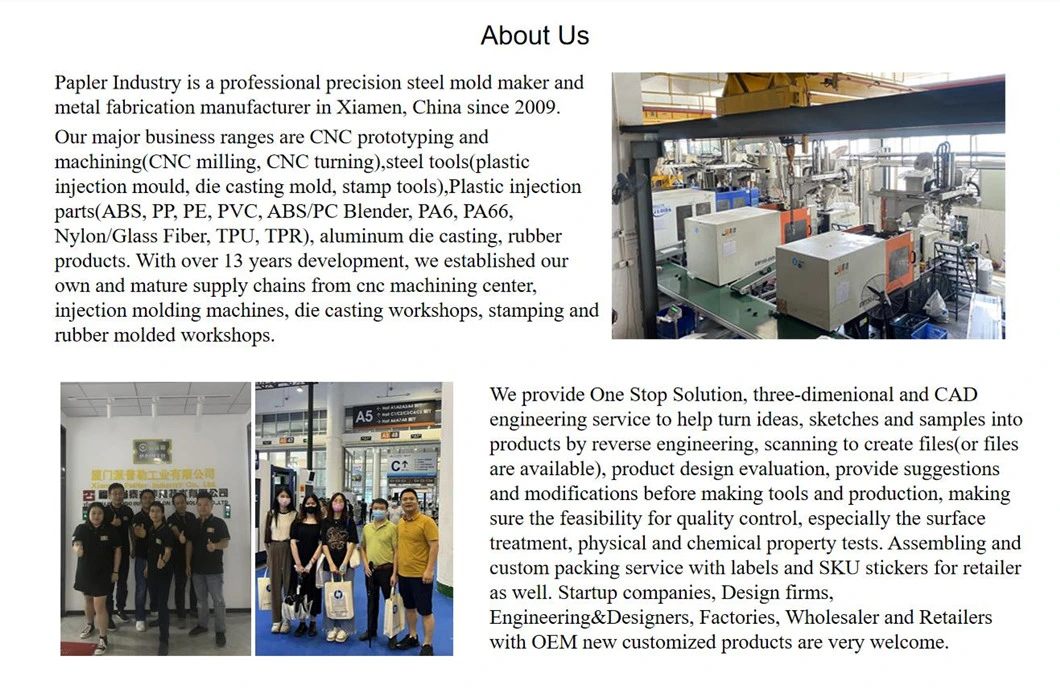

Papler Industry provides service of prototype making, mold design, mold production, mass production and assembly service in house. Our experience range from simple design to challenging technical parts.Company Profile

Packaging & ShippingFAQ1. Q: Where is your company or factory? A: We are located in Xiamen, We have our own factory.2. Q: Can you make design? A: We'll be glad to make mould designs for you, and for free. Complete mould 2D & 3D will supply to clients after order.3. Q: What type of mould you can make? A: We can make all kinds of plastic injection mould, especially rich Experience on household moulds.4. Q: What type of files can you accept? A: We can accept different types of files such as DXF, DWG, IGS, IGES, STP, PRT, X_T, PDF.5. Q: What type of steel do you use? A: P20, P20 (H), 718, 718 (H), 2738, 2738 (H), H13, NAK80,2344, S136, 4Cr13, S55C,C45#6. Q: What kind of material you use for test mould and production? A:PP, PC, PS, PE, HDPE, POM, PA6, PA66, PA6+GF, ABS, TPU, TPE, PVC, SMC, BMC, We have rich experience for manufacturing product with these materials and know how to adjust Parameter to get the perfect product.7. Q: How to send sample? A: The quotation we offer you including The cost of sample delivery 2 times samples by DHL, UPS, EMS,FEDEX or TNT.

Basic Info.

| Model NO. | PPL-P01000122 |

| Samples | Available |

| Packing | Carton Packaging, or PVC Bag with a Label; Wooden |

| Drawing | Provide by Customer(Dxf/Dwg/Prt/Sat/Iges/Step etc) |

| Surface Treatment | Electroplate, Paint Spraying |

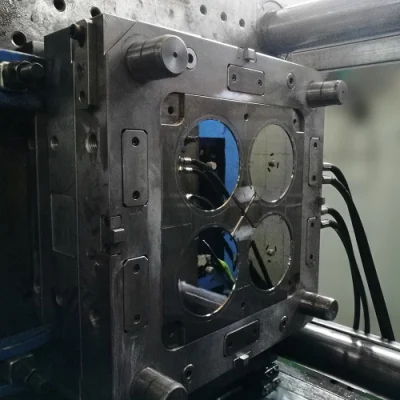

| Equipment | Injection Molding Machine |

| Material | ABS, PP, Nylon, PC, POM, TPU, PE, PBT, ABS+PC |

| Customization | Available |

| Transport Package | Carton |

| Specification | customize |

| Trademark | customize |

| Origin | Xiamen, China |

| HS Code | 3926300000 |

| Production Capacity | 2000-10000PCS/Day |

Product Description

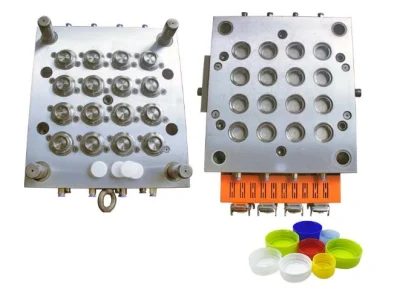

Custom Injection Molding Mould Food Grade Plastic Bottle Water Cap

Advantages:1. Free design and free sample.

2. Sign NDA.

3. ISO Certificated with the strict quality control system.

4. 13 Years OEM&ODM Mould-making,metal and plastic processing experience.

5. Good at spoken english and phone call communication.

6.One stop solution and drop shipment for online sellers.

Product Description

| Product Description | ODM plastic injection molding |

| Plastic Materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

| Standard: | ISO9001:2008 |

| Quality: | RoSH and SGS standard |

| Feature: | Non marking and Non flash |

| Size: | According to your 2D, 3D Drawing |

| Color,Quantity,Unit price,Tooling cost,Tooling size: | To be discussed |

| Package: | Standard exported Wooden box packed, Fumigation process(upon required) |

| Mold Building Lead Time: | T1, 15-25 Working days, Part measurement report (upon required). |

| Export Country: | All countries are reachable. |

| Experience: | 13 years experience in plastic injection mold making and plastic prouducts produce. |

| Mould Base: | Hasco Standard, European Standard, World Standard |

| Mould Base Material: | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment. |

| Surface Finish: | Texture(MT standard), High gloss polishing |

| Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

| Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc. |

| Mould Life: | 5,000 to 1,000,000 Shots. (According to your working environment.) |

| Design & Program Softwares: | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

| Equipments: | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

Services

Papler Industry provides service of prototype making, mold design, mold production, mass production and assembly service in house. Our experience range from simple design to challenging technical parts.Company Profile

Packaging & ShippingFAQ1. Q: Where is your company or factory? A: We are located in Xiamen, We have our own factory.2. Q: Can you make design? A: We'll be glad to make mould designs for you, and for free. Complete mould 2D & 3D will supply to clients after order.3. Q: What type of mould you can make? A: We can make all kinds of plastic injection mould, especially rich Experience on household moulds.4. Q: What type of files can you accept? A: We can accept different types of files such as DXF, DWG, IGS, IGES, STP, PRT, X_T, PDF.5. Q: What type of steel do you use? A: P20, P20 (H), 718, 718 (H), 2738, 2738 (H), H13, NAK80,2344, S136, 4Cr13, S55C,C45#6. Q: What kind of material you use for test mould and production? A:PP, PC, PS, PE, HDPE, POM, PA6, PA66, PA6+GF, ABS, TPU, TPE, PVC, SMC, BMC, We have rich experience for manufacturing product with these materials and know how to adjust Parameter to get the perfect product.7. Q: How to send sample? A: The quotation we offer you including The cost of sample delivery 2 times samples by DHL, UPS, EMS,FEDEX or TNT.

previous:

Plastic Trigger Sprayer Mold

Send to us